Which type of welding is used in pressure vessel

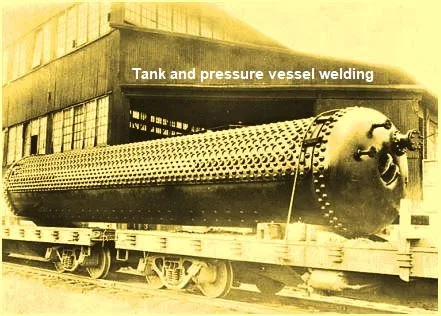

Tank and pressure vessel welding fabrication There has been an increase in both the growth of cities and towns Number and size of tanks required for storage of water, oil, natural gas, and propane. Growth in the number of automobiles, trucks, and aircraft

Increased need for storage facilities for petroleum

products. In addition, our space and missile programs

This has created the need for the storage of oxygen,

nitrogen, and hydrogen in large quantities. Fertilizer

The industry needs volume storage facilities for ammonia. The basic material for many industries that supply

Miscellaneous products such as tires, clothing, soap, and

food

Products are stored in pressure vessels. Tanks and

vessels of all kinds have become one of the major applications of welding.

Welding replaced riveting in manufacturing

of pressure vessels about 65 years ago,

It improved the service performance of a pressure vessel through the elimination of

• Elimination of caustic embrittlement in riveted boilers

drum

• Economy in weight through high joint efficiency

and the elimination of butt-straps and rivets

• Reduction in size to meet the same service

Requirements

• More flexibility of design, allowing uniform, or on

least gradual, stress distribution

• Elimination of all completed fabricating stress

vessel by heat treatment

0 Comments