Common welds and weld-related defect

|

| weld |

A weld dissection is any blockage in normal

The flow structure of a weld. barrier: May be found in the physical, mechanical, or metallurgical characteristics of the material or weld.

If discontinuity exceeds the acceptance criteria being used,

it becomes a defect. There is an imbalance in all metals, heat-affected areas,

and welds. The heat-affected zone (HAZ) is the base metal next to the weld that

did not melt but was hot enough to change its mechanical properties or its

microstructure properties. Since all metals are crystalline structures,

blockages at each grain boundary indicate an interruption in the normal flow of

the material. But size, location, extent, and other factors must be applied to

see whether the product is fit for a purpose. When a defect is indicated, it

means that the defect exceeds the allowable limits of the applicable code or

specification.

Fillet weld profile

|

| Fillet weld profiles |

Flat and concave fillet weld profiles are considered

desirable. shows a little

The convex profile is also acceptable. Thus we are reminded

again that the welder has to

Try to avoid excessive convexity. Convex fillet welds are

acceptable, provided the convexity is

within the limits indicated by

Fillet welds with overlap, a protrusion of the weld metal

beyond the weld

Toe and base metal. This can be compared to applying a wad

on the surface of the chewing gum. when the load is applied

glue, it will peel off the surface. the welded joint will

act the same way under load, and the result will be a weld

Failure. It is clear that overlap should be avoided if we

To prevent peeling of weld metal when loaded

is applicable. Joint failure is certain when there is

overlap

located in the weld. This is a serious flaw and should be

Avoid This may be due to low welding current, slow

tripping, or improper electrode manipulation.

Fillet weld with insufficient leg A reduction in leg length, means a reduction in the size

fillet weld. If the demands of a joint require a fillet of a

certain size, any reduction in that size results in a weld that does not have

the physical properties required for safe operation. The result of failure is

certain. This defect is usually caused by improper electrode angle and faulty

electrode manipulation. In addition, these defects in welding technology can

occur with very fast travel.

Fillet welds with incomplete fusion This defect are usually

found at the root of the weld and on the plate surfaces (fusion faces),

Incomplete fusion is usually caused by welding with too low current, improper

speed of travel, and/or improper electrode Is. cunning. When these conditions

are present during welding, slag inclusions and porosity (gas.) may occur in

the weld metal deposited.

trap).

Fillet welds with various other anomalies

represents a number of potential defects that may be

encountered in the base material or

weld bead.

Porosity is a cavity-type imbalance (referred to

as the form of pores) formed by the trapping of gas during

solidification. The dissections are circular and may be elongated.

contamination of filler metal or base metal or

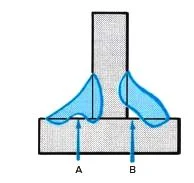

Discontinuation in single-pass double fillet welds at T-joint.

Evenly dispersed and piping porosity.

1b. Cluster porosity. and aligned porosity.

2a. Lava included.

4. Incomplete fusion.

5. Undercut.

7. Overlap.

8. Lamination.

9. Pollution. 1

0. Sew and Lap.

12a. Longitudinal

crack.

12b. transverse crack. 12c. pit crack. 12d. Throat crack.

12E. Toe crack. 12f. Root crack. 12 grams

The underbred and heat-affected zone (HAZ) cracks.

0 Comments